Colored PVB

Product Classification:

Product Introduction

Stained glass is widely used in architectural decoration, home decoration and art production. Its advantage is that it can bring unique visual and artistic effects, as well as a certain sound insulation performance. With the continuous progress of science and technology, the production process and quality of stained glass are constantly improving.It is believed that it will play a more important role in the future application field.

Technical Parameters

|

Product Thickness |

0.38mm |

0.76mm |

1.52mm |

|

|

appearance performance |

colorless or yellowish transparent smooth surface without traces |

|||

|

impurity capacity |

≤ 0.05mm2 |

no more than 5 per roll per square meter |

||

| >0.05mm2 |

not allowed |

|||

|

dimensions |

width (mm) |

500-3600 |

500-3600 |

500-3600 |

| length (m) |

20-400 |

20-200 |

100 |

|

|

length tolerance (m) |

(0-5) |

(0-2) |

(0-1) |

|

|

width tolerance (mm) |

(0-15) |

(0-15) |

(0-15) |

|

|

thickness tolerance (mm) |

±0.02 |

±0.03 |

±0.05 |

|

|

moisture content (%) |

≤0.5 |

≤0.5 |

≤0.5 |

|

|

tensile strength (mpa) |

≥ 20.0 |

≥ 20.0 |

≥ 20.0 |

|

|

resistivity (Q * 10~11) |

≥2.0 |

≥2.0 |

≥2.0 |

|

|

haze (%) |

building grade |

<0.8 |

<1.5 |

<2.0 |

| automotive grade |

<0.5 |

<0.8 |

-- |

|

|

shrinkage (%)(60 ℃/15min) |

<10 |

<10 |

<10 |

|

|

light transmittance (%) |

≥ 88.0 |

≥ 85.0 |

≥ 85.0 |

|

|

fracture growth rate (%) |

≥200 |

≥200 |

≥200 |

|

|

bond strength (mpa) |

≥ 8.0 |

≥ 8.0 |

≥ 8.0 |

|

|

tensile strength (mpa) |

>23 |

>23 |

>23 |

|

|

refractive index |

1.482 |

1.482 |

1.482 |

|

|

thermal diffusivity |

2.2*10-4 |

2.2*10-4 |

2.2*10-4 |

|

|

softening point |

95~100 |

95~100 |

95~100 |

|

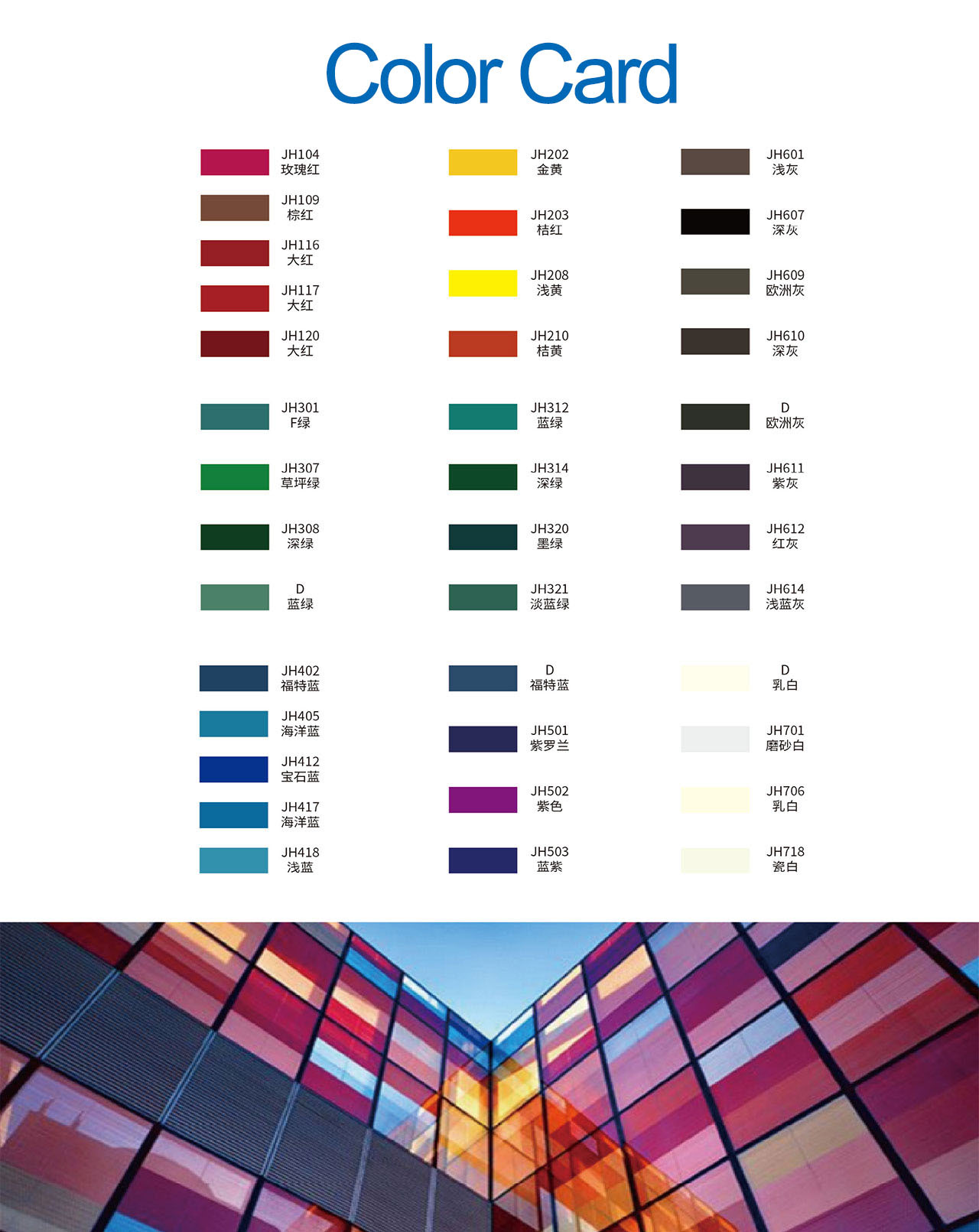

Our film can be customized according to customer requirements within 2.6 meters of various widths of the transparent PVB film, within 2.6 meters of a variety of color film. It and can also be customized according to customers' samples.

Key Words:

Online Consultation